How Long Does It Take to Become a Good CNC Programmer?

Introduction

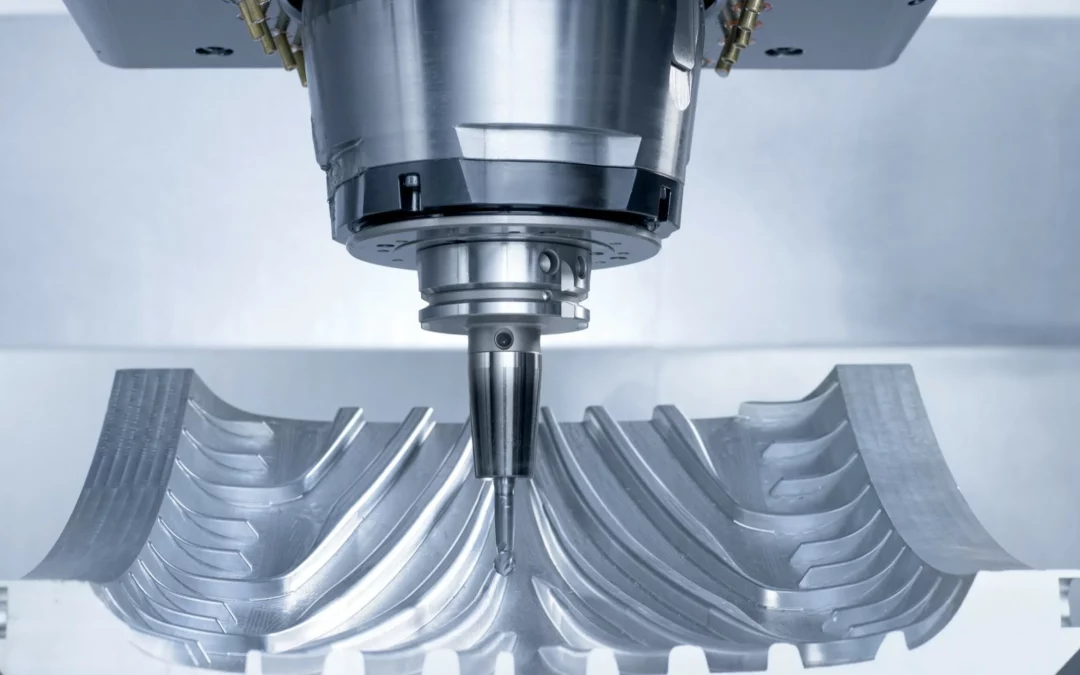

The role of a CNC programmer is indispensable in today’s manufacturing industry, as they are responsible for generating the code that guides computer numerical control (CNC) machines. The rising demand for skilled CNC programmers has prompted many to wonder about the time and dedication required to excel in this profession. In this comprehensive guide, we will explore the journey to becoming a skilled CNC programmer, focusing on the time, training, and practice needed to achieve expertise in this field.

The CNC Programmer’s Education and Training Path

Though the time needed to become proficient as a CNC programmer can vary based on an individual’s background and experience, the following steps detail the typical educational and training path:

1. High School Diploma or GED

Aspiring CNC programmers should start by obtaining a high school diploma or GED, focusing on math, computer science, and engineering courses. This foundation helps build essential skills and knowledge needed to succeed as a CNC programmer.

2. Postsecondary Education

Many CNC programmers pursue postsecondary education through vocational schools or community colleges, which offer certificate or associate degree programs in CNC programming, computer-aided design (CAD), and computer-aided manufacturing (CAM). These programs typically range from 6 months to 2 years in duration.

3. On-the-job Training and Apprenticeships

Hands-on experience is vital for cultivating the skills and knowledge needed to become a skilled CNC programmer. On-the-job training and apprenticeship programs can last between 1 and 5 years, depending on the complexity of the work and the individual’s prior experience.

Developing CNC Programming Proficiency

Becoming a proficient CNC programmer necessitates practice and continuous learning. It can take anywhere from 2 to 5 years for individuals to develop expertise in various aspects of CNC programming, such as:

1. Understanding CNC Machine Capabilities

Working with different types of CNC machines helps programmers learn about their capabilities, limitations, and ideal applications. This understanding is crucial for creating efficient and accurate programs.

2. Mastering CAD/CAM Software

Becoming proficient in various CAD/CAM software programs enables CNC programmers to create more efficient and precise toolpaths. Familiarity with industry-standard software is essential for staying competitive in the field.

3. Problem-solving and Optimization

Good CNC programmers must be able to troubleshoot issues, optimize processes, and find innovative solutions to meet the demands of the manufacturing industry. This ability requires a deep understanding of machining principles and extensive practice.

4. Gaining Industry Experience

Working in different industries, such as aerospace, automotive, and medical devices, allows CNC programmers to acquire diverse experience and skills, further enhancing their expertise and employability.

5. Staying Updated with Industry Trends and Innovations

The manufacturing industry is continually evolving, and CNC programmers must stay updated with the latest trends, technologies, and innovations. This knowledge helps them adapt to changes and maintain their competitiveness in the job market.

Continuous Learning and Skill Development

A CNC programmer’s learning journey does not end with formal education and training. Continuous learning and skill development are crucial for staying ahead in this ever-changing field. CNC programmers should consider the following to maintain their expertise:

1. Professional Certifications

Obtaining professional certifications, such as those offered by the National Institute for Metalworking Skills (NIMS), can enhance a CNC programmer’s credibility and demonstrate their commitment to ongoing professional development.

2. Attending Workshops and Seminars

Participating in workshops and seminars enables CNC programmers to learn about the latest industry developments and best practices, providing them with an opportunity to refine their skills and network with fellow professionals.

3. Joining Professional Associations

Membership in professional associations, such as the Society of Manufacturing Engineers (SME), can offer CNC programmers access to valuable resources, including industry news, educational materials, and networking opportunities.

4. Online Learning and Self-study

Online courses, tutorials, and self-study materials can help CNC programmers expand their knowledge and hone their skills at their own pace, allowing them to stay current with emerging trends and technologies.

Conclusion

The time required to become a good CNC programmer varies, but individuals can expect to invest between 2 to 5 years in education, training, and hands-on experience to develop proficiency. Continuous learning and adapting to new technologies are essential for success in this ever-evolving field. By dedicating the necessary time and effort, aspiring CNC programmers can pave the way for a rewarding and lucrative career.